The Central Electricity Authority (CEA) has recommended the implementation of targeted incentives to foster the indigenous manufacturing of critical battery components in India.

This move is deemed essential to meet the nation’s burgeoning power demand, maintain grid stability, and reduce reliance on imports, particularly from China.

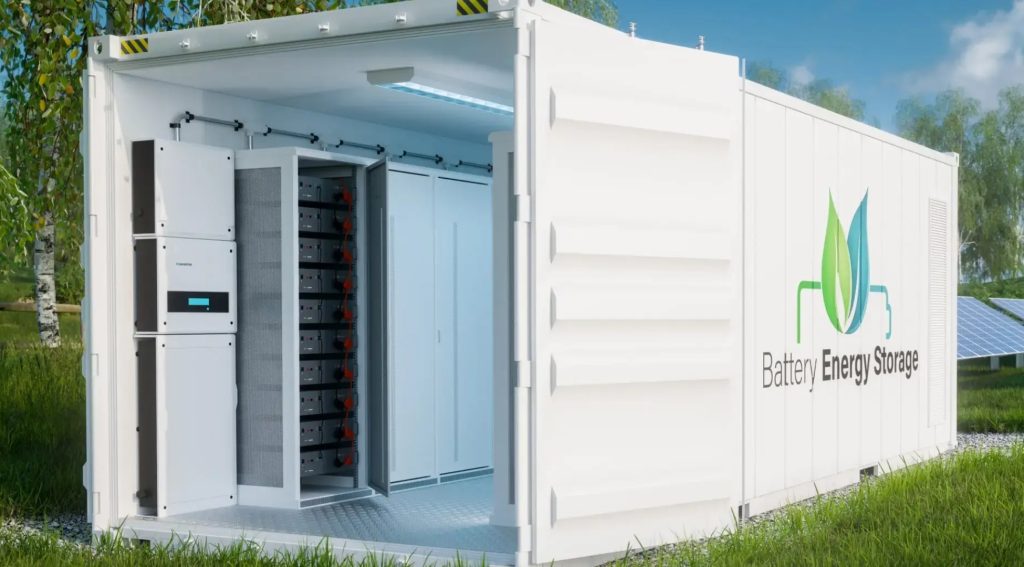

In a recent report following a workshop with key stakeholders, the CEA underscored the urgent need for local production of components such as battery management systems (BMS), fire protection systems, liquid cooling systems, and battery energy storage system (BESS) containers.

While India has made progress in cell manufacturing, the country remains heavily dependent on imports for these crucial parts, leading to increased project costs and supply chain vulnerabilities.

“There is a need to promote local manufacturing of critical battery components and create a domestic ecosystem to ensure long-term sustainability of the battery energy storage sector,” according to the report.

The CEA’s recommendations include demand aggregation mechanisms, viability gap funding (VGF), and targeted support through the existing Production Linked Incentive (PLI) scheme. These incentives are considered vital for achieving economies of scale and bringing down manufacturing costs.

The report also highlighted the necessity of integrating the battery value chain with India’s broader industrial ecosystem and raw material sourcing strategy. Currently, approximately 90% of critical minerals required for cell production are imported. The CEA emphasized the importance of securing long-term supplies through global partnerships, mineral exploration, and recycling initiatives.

Furthermore, stakeholders at the workshop, held in New Delhi in May, stressed the importance of supporting indigenous research and development (R&D) to explore alternatives to traditional lithium-ion chemistry.

With growing interest in sodium-ion, zinc-ion, and flow battery technologies, experts called for increased government funding for pilot projects and testing infrastructure. To ensure the quality and credibility of domestically manufactured systems, the CEA has also proposed establishing a national testing and certification laboratory for BESS.

India is aggressively pursuing a target of 500 GW of non-fossil fuel capacity by 2030, and robust energy storage systems are paramount to integrating intermittent renewable sources like solar and wind into the grid.

The CEA estimates a requirement of 411.4 GWh of energy storage systems by FY32. While the government had initiated a Rs 3,760 crore scheme in 2023 for large-scale battery manufacturing for power storage, a dedicated incentive scheme for battery components has been notably absent.

The CEA’s latest recommendations signify a proactive approach to plug this crucial gap in the value chain, aiming to build a robust and self-reliant battery manufacturing ecosystem in India.